Steam CV

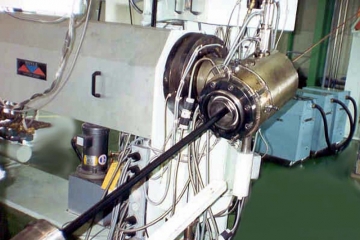

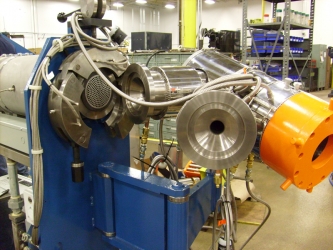

Royle manufactures a wide variety of Steam Continuous Vulcanizing (CV) lines – small to large angle catenary and vertical configurations — that are uniquely designed to optimize the performance on the wires and cables that are defined by customers for their specific projects.

Steam is the ideal medium for curing all types of low voltage rubber wires and cables, because rubber materials cannot withstand high temperatures used in radiant heated nitrogen lines. However, LV rubber cables do utilize the heat of vaporization of steam to reduce the curing time. Condensation of steam that occurs as a result of curing the rubber flows down the curing pipe and provides a lubricating surface for the insulated or jacketed cable, so that the length of the catenary curing pipe can be shorter on steam CVs.

Types of Steam CVs

CVs for automotive, appliance, electronic and similar small conductors

CVs for low voltage power distribution, flexible power, welding and similar large conductors

CVs for medium voltage power distribution cables

CVs for insulating and for jacketing of large assembled cables for power applications

Extruded Materials

All types of rubber materials, XLPE, EPDM, Silicone, CSP, Neoprene and special materials