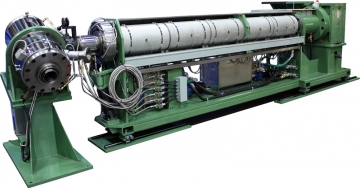

Drycure CV

Royle manufactures a wide variety of Drycure Continuous Vulcanizing (CV) lines – small to large angle catenary and vertical configurations — that are uniquely designed to optimize the performance on the wires and cables that are defined by customers for their specific projects.

The Royle Drycure CV line uses nitrogen as the pressurizing medium and zoned radiant heating that allows a unique temperature profile to be utilized in accordance with computer generated curing and cooling that is optimized for line speed performance on each conductor size and insulation thickness. The optimized temperature profile assures that the surface temperature of the extruded outer semiconducting layer does not exceed temperature limits that are defined by the material manufacturers. Nitrogen is the ideal atmosphere for curing medium and high voltage insulations, as the inert gas provides a dry pressurized atmosphere, which some users require to minimize the presence of micro voids that they believe may cause inferior electrical test performance. Since the vulcanizing pipe is hot and dry, there is no lubrication on the surface. For this reason, curing must be completed while the cable is suspended in the catenary pipe and the cable must touchdown in the cooling section which has water or gas to cool the cable.

Types of Drycure CVs

CVs for LOW VOLTAGE power distribution in industrial and utility applications

Triple CVs for MEDIUM VOLTAGE power distribution in industrial and utility applications

Triple CVs for EXTRA HIGH VOLTAGE power distribution in utility applications

Extruded Materials

All types of XLPE and EPDM materials