AutoLine Controls

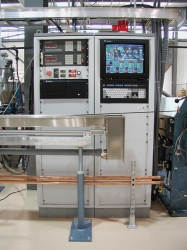

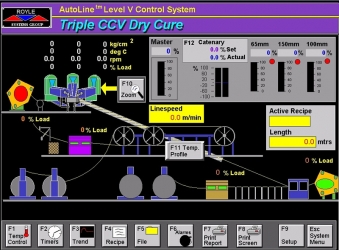

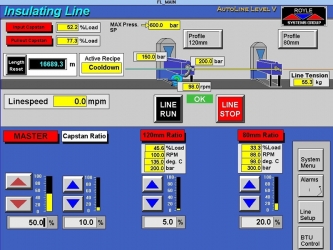

Royle products are designed to control our range of production lines and are marketed under the trade name autoLine. The basis of the automation is a PLC that is programmed for each specific application to integrate every component – all drives, temperatures, pressures, etc – to function as a system and as required by the unique process. The system provides full alarm functions for troubleshooting and full recipe functions for parameter setup and repeatability of process. The autoLine system has an industrial computer with SCADA software and a large HMI color touchscreen with screens that are friendly to operators. Key parameters and features of the system are locked and accessible only to the supervisor(s), who are responsible for the performance of the production line. The autoLine system is capable of linking to the Internet or the customer’s LAN system.

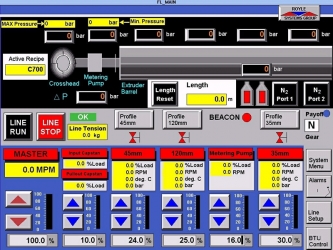

AutoLine Systems Features:

Industrial LAN Networking

Process Overview

- Extruder Speed Setting (Course & Fine)

- Actual Screw Speed

- Extruder Melt Pressure

- Extruder Melt Temperature

- Extruder Motor Load

- Capstan Speed Setting(Course & Fine)/Actual

- Capstan Motor Load

- Length Counter

Temperature Overview

- Extruder Zone Setpoints

- Extruder Zone Process Values

- Extruder Zone Output Values

Alarm Overview

- Emergency Stop

- Motor/Drive Alarm (Fault/Motor Thermal)

- Line Alarm

- Temperature Alarm

- Process Alarms (High/Low Temp, Water level, Loss of Air pressure)

Recipe Save/Upload/Download

- Recipe Name as alpha numerical Product ID.

- Extruder Temperature Zone Setpoints

- Capstan/Extruder Speed Settings

- Catenary Temperature Zone Setpoints (Temperature setpoint changes with Line Speed)