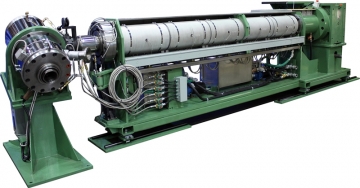

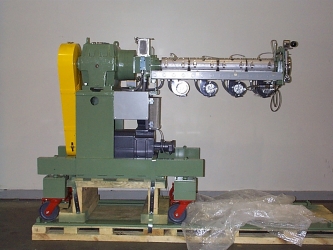

Extruders

Royle manufactures extruder designs for all types of thermoplastic and thermosetting materials with different features to suit a wide range of applications. Each extruder is uniquely designed to optimize the performance on wire and cable, shapes, tubes, mold prep slabs, compounding, straining and other special applications that are defined by customers for their specific projects.

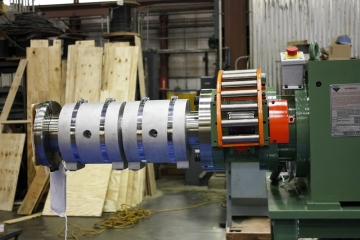

Extruder Heating and Cooling Systems

Royle has three designs for heating and cooling the extruder barrel to optimize the performance on specific types of extruded materials.

Royle Extruders with Alufin System

The Alufin model uses aluminum castings in 180⁰ segments with internal heater and external cooling fins. Two segments are bolted to the barrel, a cooling blower is mountedbelow the barrel and a thermocouple is installed in the barrelfor each control zone. The extruder PID temperature loops control the setpoint by adding or removing heat to maintain the desired melt temperature of the extruded material. The Alufin system is generally used for materials that require heat input and have melt temperatures greater than 150⁰C.

Royle Extruders with Alurobe System

The Alurobe model uses aluminum castings in 180⁰ segments with internal heater and cooling channels. Two segments are bolted to the barrel, a solenoid valve is connected to the outlet of the cooling channel and a thermocouple is installed in the barrel for each control zone. A closed circuit system circulates a heat exchange fluid through the cooling channels of the aluminum castings to remove heat from the barrel.The extruder PID temperature loops control the set point by adding or removing heat to maintain the desired melt temperature of the extruded material. The Alurobe system is generally used for materials that require heat removal and have melt temperatures less than 150⁰C.

Royle Extruders with Aluroyle System

The Aluroyle model uses aluminum castings in 180⁰ segments with internal cooling channels. Two segments are bolted to the barrelfor each control zone. As an option, a solenoid valve can be connected to the outlet of the cooling channel, a thermocouple installed in the barrel and a closed circuit system supplied to circulate a heat exchange fluid through the cooling channels of the aluminum castings to remove heat from the barrel. The Aluroyle system is generally used for materials that require only removal of heat and have melt temperatures less than 100⁰C.

Extruder L/D Ratios for Different Materials

Less than 10 L/D for direct hot feed of rubber strips from mills or drops from mixers, or reclaim for straining

15 to 20 L/D for direct feed of room temperature rubber strips

24 to 36 L/D for thermoplastic and some thermosetting materials

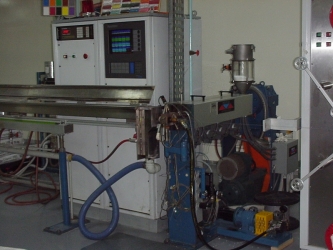

Accessories for Extruders

Loading and drying systems for pellets

Volumetric and screw feeding systems for primary material and color or other types of additives

Roller feed with variable speed drive for rubber strips and quick features for color change or pellet feed

Heads of many types for wire/cable, tubes, shapes, slabs, noodles or pellets

Gas injection system for foam PE and fluoropolymers

Extruded Materials

All types of standard and special screw designs for thermoplastic, rubber and other thermosetting materials